Thanks to PILLET company (integrated into TECNAL since 1996), I acquired a very special know-how, the production of casein and caseinates.

The word “casein” comes from the Latin caseus, “cheese”. These are the major milk proteins (82% of total protein). Caseins give milk its white color and are essential to its transformation into yogurt, cheese …

Caseins are widely used as a food ingredient (in ice cream, yogurt, meats, sauces …), but also in cosmetics, chemicals (paint binder) and even once to make pretty buttons for clothes!

Hydrolysis of casein revealed high levels of glutamic acid, proline, leucine, lysine, serine and threonine.

There are several fragments of casein in the milk. These are the most α1 caseins, α2, β, γ and K (or kappa).

The extraction and valorisation of casein is the specialty, globally recognized PILLET, now part of TECNAL, a specialist cheese and dairy process.

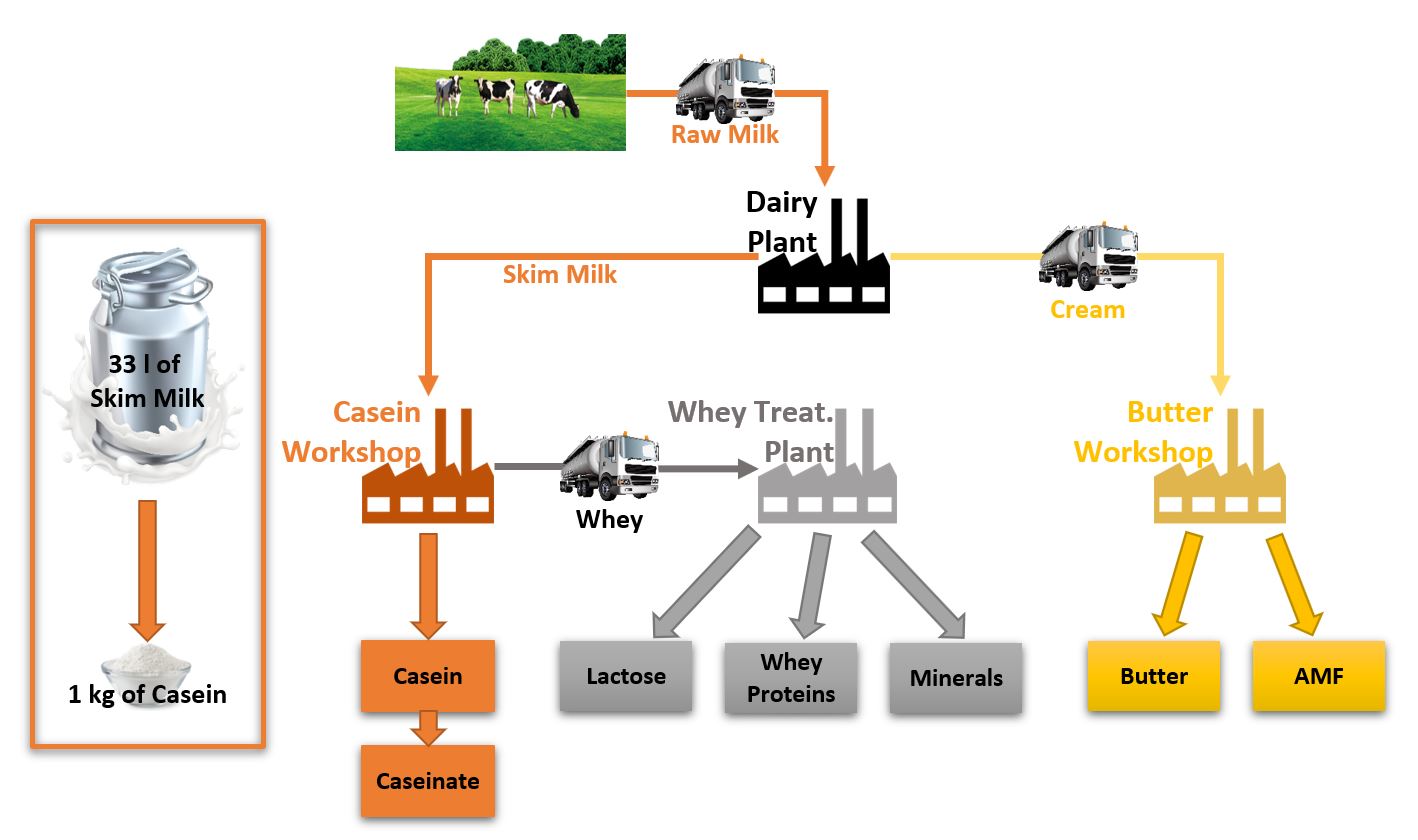

Casein Production:

A very special process …

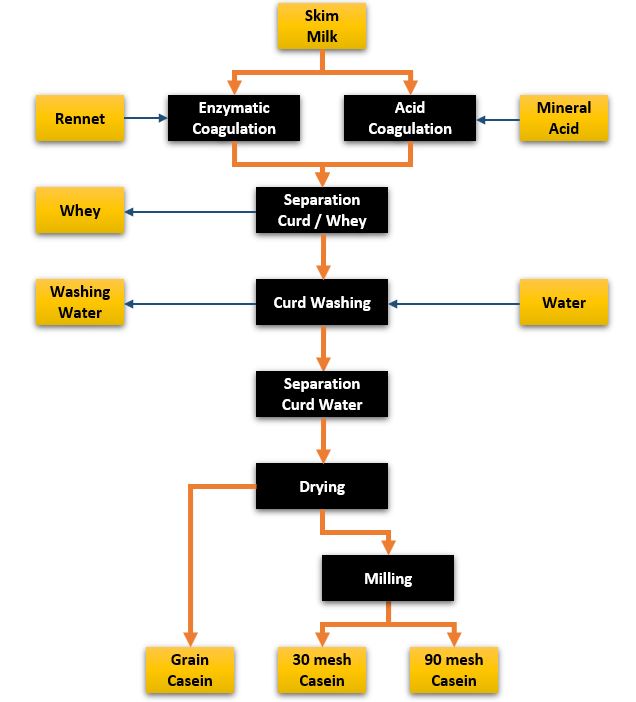

The extraction process of the caseins is very specific. The main steps are:

- Coagulation of skim milk, obtaining a curd

- Solid (curd) / liquid (whey) separation by centrifugation

- Purification of curd grains (“washing”)

- Drying in a vibro-fluidized dryer

- Optionally grinding of the grains

- Coagulation Tube

- PILLET Washing Towers

- Centrifuge Decanter

- PILLET Fluid Bed Dryer (double deck)

Two types of caseins :

There are basically two types of casein:

- “Acid” Casein, obtained by coagulating with hydrochloric acid (or, more rarely with lactic acid)

- “Rennet” Casein, obtained by coagulation with rennet (like cheese).

The modern production units, the casein plants, have a “continuous” process. For “rennet” casein, some maturation tanks are needed, that is a semi-continuous production by switching successive tanks. Note that there is still very little developed, a 100% continuous process for this type of casein.

Caseinates Production:

Why the Caseinate?

Caseins obtained by the acidification of the milk are insoluble at neutral pH. In order to provide the use as a food ingredient, it is necessary to conduct a chemical “neutralization” with a base.

Several type of Caseinate?

Depending on the base used, we obtain different types of caseinates with slightly different properties:

- Sodium Caseinate

- Calcium Caseinate

- Potassium Caseinate

Neutralization: How?

The neutralization operation can be done in 3 ways:

- From curd, by adding a base into the tank. This method, at “low concentration”, then requires a drying operation in spray tower. This produces a “spray caseinate”, with interesting properties, but this ways is preferred especially if you already have a spray tower.

- From casein already dried, dissolved in a basic solution. This process, at “low concentration” also continues as the previous one. Note that here the product was dried 2 times, which energy is rather questionable.

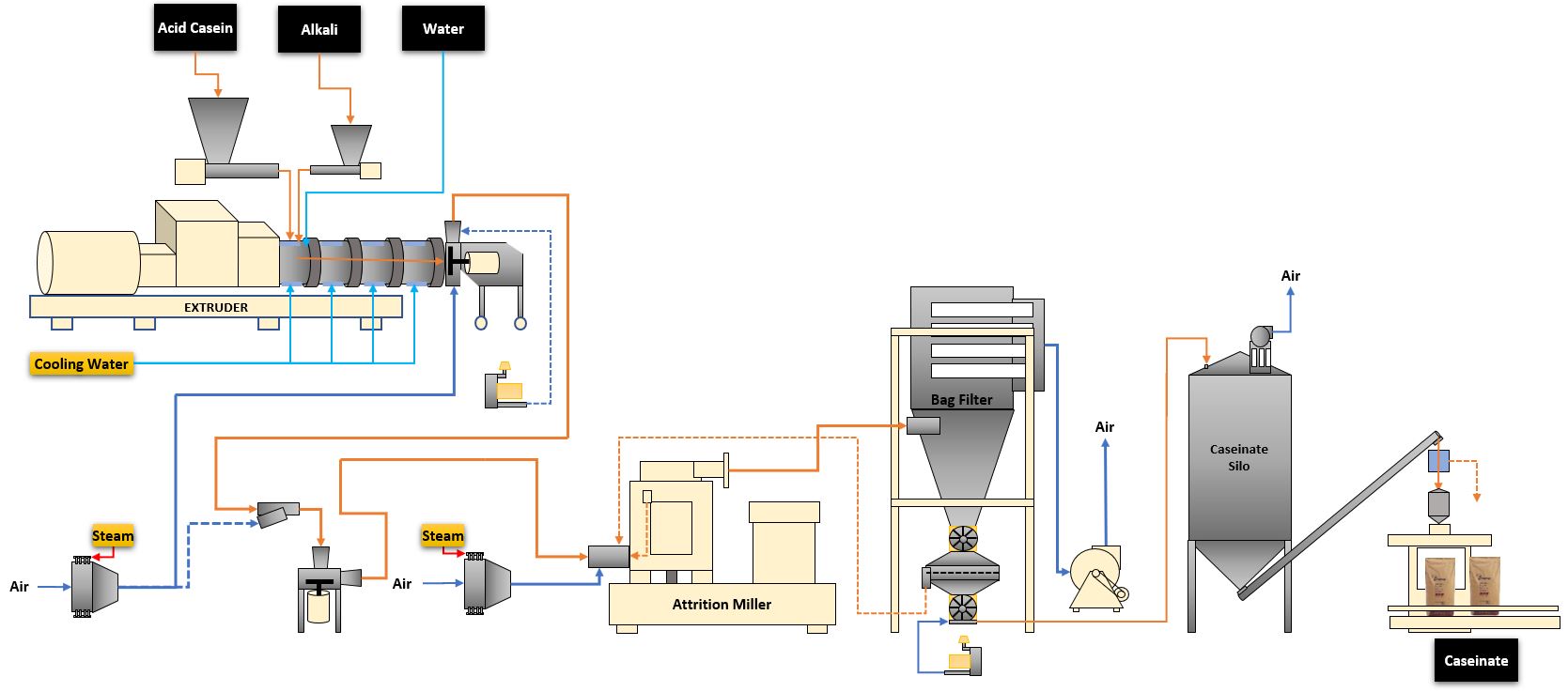

- From dry casein, a “high concentration” method by using “Extrusion” technology to perform the reaction.

The “Extrusion” technology, what is it?

This modern process developed by PILLET therefore allows you to make the neutralization reaction with a minimum of water, hence the term “high concentration”.

This production line is compact and energy efficient.

- Double screw Extruder

- Cutting

- (Français) Pré-broyage Pre-milling

- Attrition Milling

- (Français) Filtration et tamisage Filtration and Sieving